Arcelor Mittal is a leader in producing the advanced lightweight steels used to make the design-forward, performance-driven and safety-superior vehicles of today and tomorrow. The company’s network of global research and development teams work directly with customers to develop steel products and solutions for next-generation vehicles.

Steel produced by ArcelorMittal Dofasco in Hamilton and ArcelorMittal Tailored Blanks’ innovative laser welding technology for multi-part integration play a key role in the engineering and design of Project Arrow, the first Canadian all-electric, zero-emission vehicle.

The Project Arrow concept vehicle, recently showcased at the Canadian International Auto Show in Toronto, is a project of the Automotive Parts Manufacturers Association in collaboration with more than 50 partners. Designed, engineered, and built in Canada, the car is an answer to the Canadian government challenge to be at net zero by 2050.

“The advanced vehicles of the future will need a wholistic approach to range, structural integrity and enterprise responsibility,” said Flavio Volpe, President of the Automotive Parts Manufacturers’ Association.

“ArcelorMittal was the perfect partner for Project Arrow to showcase the advanced manufacturing, use case and advantage of the Canadian steel of the future.”

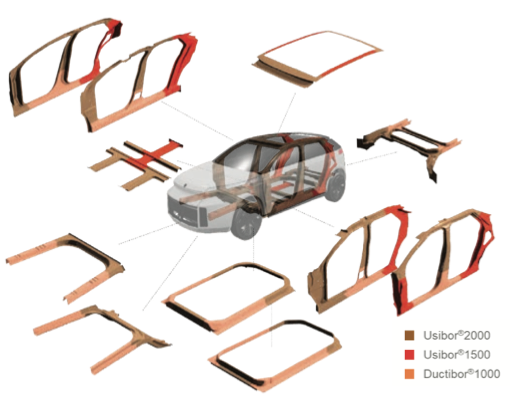

Project Arrow showcases innovations in steel and in laser welded blanks (also called tailored blanks), which allow automakers to reduce the weight of their vehicles while improving safety by combining different steel grades with different coatings and thicknesses into one single part.

“The innovations with laser welded blanks in the APMA concept vehicle are made possible by ArcelorMittal’s range of press hardenable steels (PHS) that include the Usibor® and Ductibor® families,” says Ram Iyer, Manager, Co- Engineering, Auto Product Applications, ArcelorMittal Global Research and Development.

ArcelorMittal Dofasco began producing Usibor® press hardenable steel (PHS) in Hamilton in 2022 after a $24-million CAD coating addition at its No.5 Hot-Dipped Galvanizing Line. It is the only producer of this aluminum alloy coated press hardenable steel in Canada.

PHS grades are ultra-high strength and formed at high temperature into complex shapes. Following rapid cooling in the die, the strength of the part increases significantly. They are intended for use in the structural and safety components of vehicles, notably in the safety cage that protects the occupants in all crash events, says Iyer.

“These new grades are enabling OEMs to take the crash and safety performance of their vehicles to even higher levels while reducing material use and ad- dressing burgeoning sustainability targets. Vehicle models that utilize these grades are in production both in North America and globally. ArcelorMittal continues its research and development in steel grades for the automotive industry and is committed to bringing many new products into its PHS family.”

ArcelorMittal Tailored Blanks (AMTB) supported the Project Arrow team in developing a virtual model of the vehicle and co-engineered the Multi-part Integration (MPI) concepts that showcased laser welded blanks using the PHS steels says Gagan Tandon, Vice President, Product Development for ArcelorMittal Tailored Blanks Americas.

“Multi Part Integration concepts are laser welded blanks that consolidate multiple components into a single hot stamped design, which reduces the complexity of the body assembly for manufacturers. As a part of the Body-In-White

Electric Vehicle

(BIW) development, more than 60 parts were consolidated into 11 integrated parts for Project Arrow.”

Together, the innovative steel grades applied to multi part integration save 15 per cent of component weight on the BIW and the Multi-part Integration concepts reduce emissions per vehicle during production by 30 per cent due to part consolidation, efficient processes, and a reduced number of operations and logistics.

ArcelorMittal has a global commitment to reduce GHGs by 25 per cent by 2030 and a net zero target for 2050. It’s XCarbTM brand brings together the company’s reduced, low and zero-carbon products and steelmaking activities, as well as wider initiatives and green innovation projects, into a single effort focused on achieving demonstrable progress towards carbon neutral steel. – In Ontario, ArcelorMittal Dofasco has begun offering XCarbTM recycled and renewably pro- duced (RRP) steel to its customers. RRP steel has a minimum of 70 per cent scrap steel content.

Two ArcelorMittal investments in Ontario are also contributing to a lower carbon future.

ArcelorMittal Tailored Blanks has invested $17.4 million in new equipment and modifications to its Woodstock, Ont. facility to produce advanced tailor blanks for door ring applications to address increased production demands in the battery electric vehicle market. Southwestern Ontario Development Fund contributed $1.5 million to the project.

ArcelorMittal Dofasco has embarked on a transformation which will make it the first integrated steel mill in North America, and among the first in the world, to transition off coal for the iron making process. The site will move to electric arc furnaces (EAFs) that are fed with direct reduced iron (DRI) produced on- site, which will cut greenhouse gas emissions by approximately 60 per cent, or 3 million tonnes, by 2028.

That is the equivalent of taking 725,000 internal combustion engine cars off the road or planting 138 million trees.

The nearly $2-billion investment is supported by $400 million from the federal government and $500 from the provincial government.

Want to know more about ArcelorMittal? Click here.

For more articles on innovation, click here.