Hamilton has a key role to play in the Advanced Manufacturing supercluster, a network in Southern Ontario that is one of nine shortlisted Supercluster proposals across Canada.

The Ambitious City is a 170-year old Hamilton moniker that stands true today – Hamilton is a vibrant, dynamic, growing and sustainable community.

The city has had a lot of handles over the years: Lunch-Bucket Town, The Birmingham of Canada, Electric City, Tiger Town, and more recently, The Hammer, City of Waterfalls and Music City. Hamilton is none of these, yet all of these.

It’s tempting to pursue one label, one industry…the silver bullet. There is no silver bullet and a label offers only one dimension of a community. Perhaps for Hamilton, the most prevalent is “Steeltown.”

But it’s never been just about steel. It’s about a depth and breadth in manufacturing that was the envy of other economies from the second half of the 19th century to the late 20th century. Hamilton was a model of the mass production economy.

What happened to the economic foundation of that mass production economy? The easy narrative is: “The factory lines stopped rolling. They packed up and left behind a city in significant economic decline.”

There’s no denying manufacturing across Canada has changed dramatically. Many manufacturers left – taking predominantly labour jobs to lower-cost jurisdictions in the southern USA or Mexico. Hamilton experienced the same. Although at the bottom of a cycle, it also faced an opportunity for renewed growth in a maturing economy.

ArcelorMittal Dofasco, long a central pillar in the city’s manufacturing economy, made the shift to higher value customer-centric solutions in steel to combat this threat and seize an opportunity. The company took its seat on a technology train gathering significant speed towards a turning century.

Brute force no longer drives manufacturing, technology does. Today’s manufacturing is rooted in the information age economy, driven by the advances in data, automation and robotics. The digitization of industry is here and has companies combining advanced connectivity, data analytics, cloud computing, sensors, intelligent algorithms and deep machine learning to transform their business.

There is a long way to go, but Canadian manufacturers like ArcelorMittal Dofasco, the country’s largest flat roll steel producer, are on the curve. There are also many questions to answer including how to continuously reduce environmental impact of industry including rapidly and significantly decreasing GHG emissions. What will future manufacturing look like? It won’t look the same inside or out, but making things will continue to be an economic engine.

Here lies Hamilton’s continued opportunity.

Hamilton has been on the rise for some time. The Conference Board of Canada consistently ranks Hamilton as the most diverse economy in the country. Right now, industrial manufacturing within Hamilton represents about $12 Billion annual effect or the equivalent of 4 per cent of Ontario’s GDP. Although Hamilton has an incredible breadth and depth of advanced manufacturing, a significant portion of that is small and medium size enterprises.

The opportunity is to scale these businesses up.

Enter the Government of Canada’s $950 million supercluster strategy designed to focus business, research, and government leaders on key sectors where Canada can drive innovation and remain internationally competitive. The Advanced Manufacturing Supercluster is a network in Southern Ontario that was announced as one of nine shortlisted Supercluster proposals across the country. The final Superclusters will be announced in 2018.

Hamilton has a key role to play in the Supercluster which would be a network of service oriented solution providers that will help those 1,000 small and medium manufacturers adopt the technology that will grow them into 1,000 people or more organizations. The Supercluster would leverage and connect our significant research assets, including universities, national labs and private sector organizations and create an interface that brings together technology providers and manufacturers to help them with just that, creating a significant ripple effect for the economy and our communities.

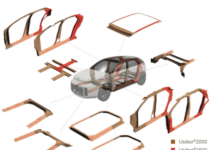

Large manufacturers bring significant impact to host communities. Consider ArcelorMittal Dofasco. Its 100-plus grades of made in Hamilton steel are transforming the design, performance and sustainability of autos as well as creating stronger, safer and more sustainable buildings, innovative new packaging as well as supporting emerging technologies in the tubular energy market.

Dofasco produces 4.5 million tons of steel for use across Canada, in the USA and in Mexico and its raw materials and supplies used in its processes come from all over North America. These comings and goings utilize truck, rail, vessel and barge and are a significant boon to the transportation and logistics industries in the community. The company has an annual spend of nearly $3 billion each year, most which is local to the Hamilton area. That includes everything from wages to contracting and raw materials to safety equipment.

Also critical are the indirect jobs manufacturers create. ArcelorMittal Dofasco employs 5,000 directly, but also creates an additional 20,000 jobs related to its business. These jobs are a diverse set of skills and disciplines from operations, to professional, technical, skilled trades and service based positions.

This is the connectivity and impact that Hamilton is having through just one large manufacturer.

The Advanced Manufacturing Supercluster would provide the 1,000 small and medium size manufacturers in Hamilton an opportunity to rapidly adopt technology to grow and have a similar impact. These businesses need counsel and solutions to make it happen and the Advanced Manufacturing Supercluster is the missing infrastructure to help them.

Hamilton has the foundation of existing and proven businesses that will be central to Supercluster success. It is the Ambitious City that is well-positioned for continued growth anchored in making things.

Read the full Perspective Hamilton 2017 feature here.