By Dylan Kristy, University of Windsor

Researches at the University of Windsor are making sure the Automotive Capital of Canada remains in the driver’s seat as the industry travels ahead into alternative metal forming, vehicle efficiency and vehicle-to-vehicle communication.

State-of-the-art laboratories in the Faculty of Engineering work hand- in-hand with Original Equipment Manufacturers (OEMs) to analyze and refine parts and materials to directly assist in building the vehicles of tomorrow.

In the heart of the Ed Lumley Centre for Engineering in Narayan Kar’s lab sits an electric motor from the Ford Motor Company of Canada.

A motor that has been scrutinized by researchers and engineers for countless hours to get it to its current high level of efficiency.

And yet, the University of Windsor engineering professor has set out to take that motor and make it even better.

“Our work will never end, and this will always be an open-ended problem,” said Dr. Kar.

“There will always be an opportunity to make them lighter, more compact and more efficient.”

Kar’s lab, the Centre for Hybrid Automotive Research and Green Energy (CHARGE), is examining the challenges that are created when engineers work to make electric motors in consumer vehicles more compact and lighter to increase the driving range.

Next door to CHARGE Labs is Kemal Tepe’s Wireless Communication and Information Processing Lab, where his team researches autonomous driving through vehicle-to-vehicle communication, connected vehicles and network security.

“Right now, we have the technology to have level three autonomy in vehicles with lane change detection, blind spot detection and active cruise control,” Dr. Tepe said.

“But moving to level four or five autonomy requires a little more sophistication.”

Tepe said level five autonomy would allow drivers to program in their destination and have the vehicle do all the navigating, but the computer power doesn’t exist yet to make it feasible for consumers.

“The problem is running the algorithms, or the car’s brain, fast enough to do these calculations in real time and to interact with other vehicles,” Tepe said.

While the automotive industry is looking to lightweight materials as an alternative to steel as a way to improve fuel efficiency, lower-density materials can have limited formability.

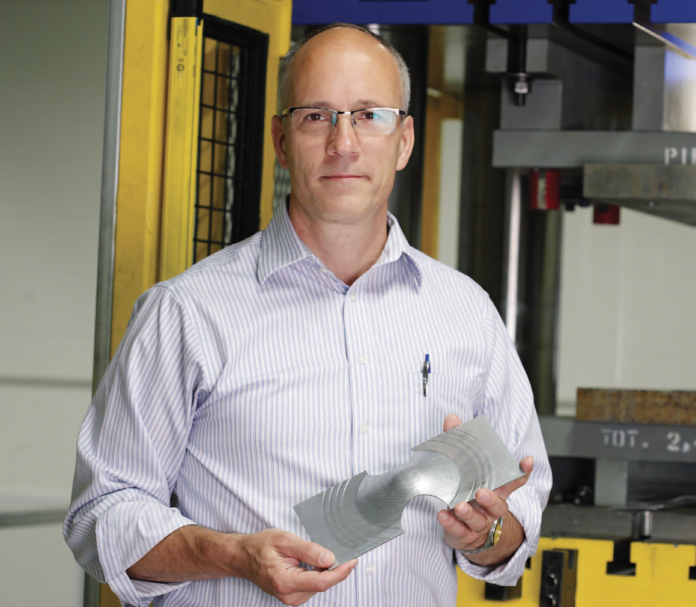

Daniel Green, an associate professor in the Faculty of Engineering, said innovative forming processes need to be developed and optimized for the production of automotive parts.

“With high-speed forming, we can get 100 per cent more formability than we can with conventional stamping,” he said.

Dr. Green recently received funding towards modelling the deformation and failure of sheet metal in high-strain rate forming.

Just behind the Centre for Engineering Innovation is the University of Windsor’s Centre for Automotive Research and Education.

The Noise,Vibration and Harshness- Sound Quality Research Group focuses on automotive- and computer- related sound, with a focus on psychoacoustics.

Colin Novak, a professor with the Faculty of Engineering, said his team often works with OEMs to hone the sounds produced by automobiles.

Dr. Novak said a good example is taking an inexpensive vehicle with a light door and engineering it to have an “authoritative thud when you close it.”

“If the door sounds like that of an expensive car then people get the impression this car must be of good quality,” Novak said.

He said the University of Windsor is the best-equipped school in Canada for noise measurement with its anechoic chamber, durability shaker, several microphone arrays that allows researchers to see and measure the sound and binaural heads.

“The binaural heads look like a person’s head but have microphones inside the ear canal,” Novak explained.

“The shape of our nose, chin, upper body and ear canal all affect how we hear sound and so when we evaluate sound it’s important to measure it against how a person would perceive it.”

Ming Zheng is looking to revolutionize a product that hasn’t changed much in the last 100 years.

Dr. Zheng’s Clean Combustion Engine Lab has taken a conventional spark plug and improved it by creating a multi-pole spark ignition.

“Currently, vehicles are designed with gasoline engines operating with the best possible gasoline,” Zheng said.

“But as we move to ethanol or other alternative fuels, you will need a stronger, better and more effective ignition source.”

Zheng said the potential is so great for the three-pole spark plug, that “every major automotive manufacturer in the world is watching what we’re doing.”

If you require more information about this story or the Windsor-Essex Region, please connect with one of the business professionals at Windsor-Essex Economic Development Department who will assist you with location and investment decisions – please email info@choosewindsoressex.com or visit Choose Windsor Essex